Ultra

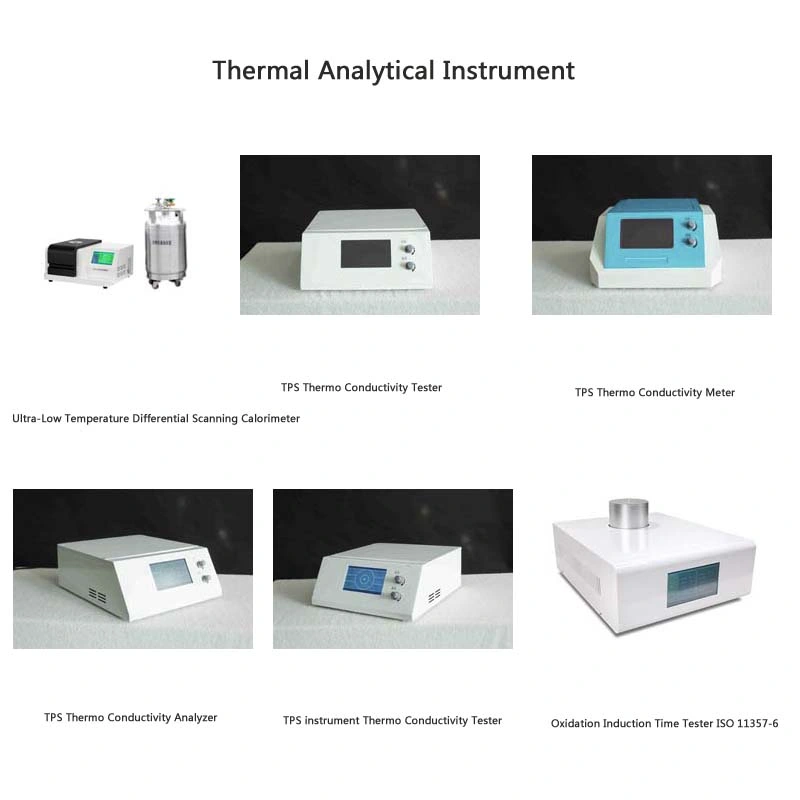

Overview Package Size 30.00cm * 30.00cm * 30.00cm Package Gross Weight 5.000kg Ultra-low temperature differential scanni;

Overview

Ultra-low temperature differential scanning calorimeter

Model

GB/T 19466.2 - 2004/ISO 11357-2:1999 Part 2: Determination of glass transition temperature;

GB/T 19466.3 - 2004/ISO 11357-3:1999 Part 3: Determination of melting and crystallization temperature and enthalpy.

GB/T 19466.4 - 2016/ISO 11357-4:1999 Part 4: Determination of specific heat capacity;

The differential scanning calorimeter is used measure the physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, heat of crystallization and crystallization, heat of phase transition reaction, thermal stability of products, curing/crosslinking, oxidation induction period, etc.

Features1. The new fully closed metal furnace body design structure greatly improves the resolution and resolution as well as better baseline stability.

2. Professional alloy sensor is adopted, which is more resistant to corrosion and oxidation and has high sensitivity.

3. Perfect two-way atmosphere control system, precise control of purge gas flow, automatic switching of software settings, and direct recording of data in the database.

4. The Cortex-M3 core ARM controller is adopted, with faster calculation and processing speed and more accurate temperature control.

5. USB two-way communication is adopted, which is more convenient to operate and supports the self-recovery connection function.

6. The 7-inch 24-bit full-color LCD touch screen is used to display the status and data of the instrument in real time.

7. The instrument is equipped with standard materials. Users can calibrate each temperature range by themselves to reduce the error of the instrument.

8. Intelligent software design, automatic drawing of the whole process of the instrument, the software can realize various data processing, such as calculation of enthalpy, glass transition temperature, oxidation induction period, melting point and crystallization of substances, etc.

Specifications1. DSC range: 0 -± 500mW

2. Temperature range: -150 ºC~600 ºC fully automatic pressurized liquid nitrogen tank

3. Temperature resolution: 0.01 ºC

4. Heating rate: 0.1~80 ºC/min

5. Cooling rate: 0.1~50 ºC/min

6. Temperature repeatability: ± 0.1 ºC

7. DSC noise: 0.01mW

8. DSC resolution: 0.01mW

9. DSC accuracy: 0.01mW

10. DSC sensitivity: 0.1mW

11. Temperature control mode: heating, cooling, constant temperature, any combination of three modes for recycling

12. Curve scanning: temperature rise scanning

13. Atmosphere control: instrument automatic switching

14. Gas flow: 0-200mL/min

15. Gas pressure: 0.2MPa

16. Display mode: 24bit color 7-inch LCD touch screen display

17. Data interface: standard USB interface

18. Parameter standard: equipped with reference material and one-button calibration function, users can calibrate temperature and enthalpy by themselves

19. Working power supply: AC 220V 50Hz or customized

20. Power 300W

Detailed Photos

Basic Info.

| Model NO. | DSC-600UL |

| Standard | GB/T 19466.3-2009 |

| Application | Low Temperature Testing Machine |

| Shipping Way | Air, Sea, Land |

| Supply Area | Global |

| Transport Package | Wooden, Carton |

| Specification | DSC-600UL |

| Trademark | SRI |

| Origin | China Mainland |

| HS Code | 8419899090 |

| Production Capacity | 500 Sets Per Year |

Packaging & Delivery

Package Size 30.00cm * 30.00cm * 30.00cm Package Gross Weight 5.000kgProduct Description

Ultra-low temperature differential scanning calorimeter

Model

DSC-600UL

StandardGB/T 19466.3 - 2009/ISO 11357-3:1999 Part 6 Determination of oxidation induction time (isothermal OIT) and oxidation induction temperature (dynamic OIT) during oxidation induction period;GB/T 19466.2 - 2004/ISO 11357-2:1999 Part 2: Determination of glass transition temperature;

GB/T 19466.3 - 2004/ISO 11357-3:1999 Part 3: Determination of melting and crystallization temperature and enthalpy.

GB/T 19466.4 - 2016/ISO 11357-4:1999 Part 4: Determination of specific heat capacity;

The differential scanning calorimeter is used measure the physical and chemical changes related to heat, such as glass transition temperature, melting point, melting temperature, heat of crystallization and crystallization, heat of phase transition reaction, thermal stability of products, curing/crosslinking, oxidation induction period, etc.

Features1. The new fully closed metal furnace body design structure greatly improves the resolution and resolution as well as better baseline stability.

2. Professional alloy sensor is adopted, which is more resistant to corrosion and oxidation and has high sensitivity.

3. Perfect two-way atmosphere control system, precise control of purge gas flow, automatic switching of software settings, and direct recording of data in the database.

4. The Cortex-M3 core ARM controller is adopted, with faster calculation and processing speed and more accurate temperature control.

5. USB two-way communication is adopted, which is more convenient to operate and supports the self-recovery connection function.

6. The 7-inch 24-bit full-color LCD touch screen is used to display the status and data of the instrument in real time.

7. The instrument is equipped with standard materials. Users can calibrate each temperature range by themselves to reduce the error of the instrument.

8. Intelligent software design, automatic drawing of the whole process of the instrument, the software can realize various data processing, such as calculation of enthalpy, glass transition temperature, oxidation induction period, melting point and crystallization of substances, etc.

Specifications1. DSC range: 0 -± 500mW

2. Temperature range: -150 ºC~600 ºC fully automatic pressurized liquid nitrogen tank

3. Temperature resolution: 0.01 ºC

4. Heating rate: 0.1~80 ºC/min

5. Cooling rate: 0.1~50 ºC/min

6. Temperature repeatability: ± 0.1 ºC

7. DSC noise: 0.01mW

8. DSC resolution: 0.01mW

9. DSC accuracy: 0.01mW

10. DSC sensitivity: 0.1mW

11. Temperature control mode: heating, cooling, constant temperature, any combination of three modes for recycling

12. Curve scanning: temperature rise scanning

13. Atmosphere control: instrument automatic switching

14. Gas flow: 0-200mL/min

15. Gas pressure: 0.2MPa

16. Display mode: 24bit color 7-inch LCD touch screen display

17. Data interface: standard USB interface

18. Parameter standard: equipped with reference material and one-button calibration function, users can calibrate temperature and enthalpy by themselves

19. Working power supply: AC 220V 50Hz or customized

20. Power 300W

Detailed Photos

You may also like

Send inquiry

Send now